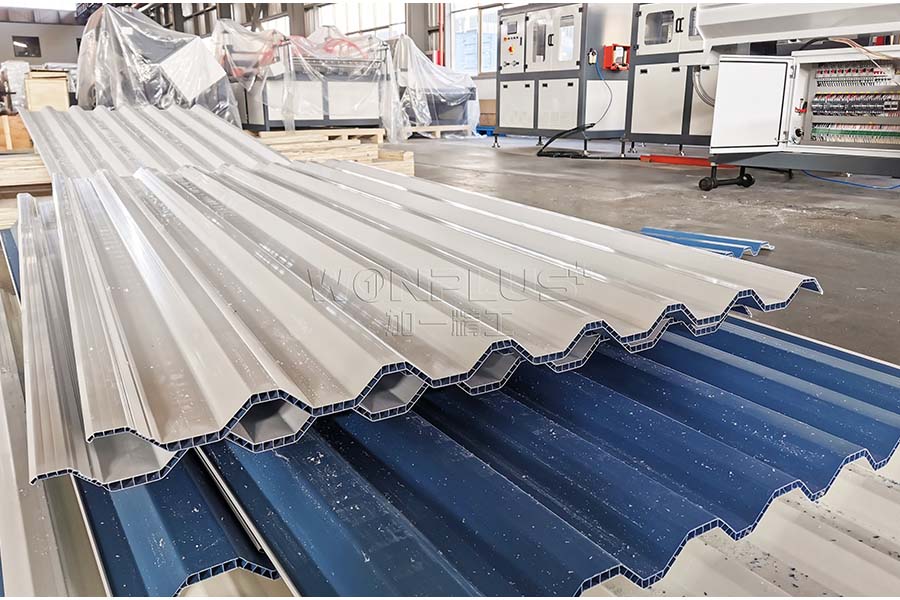

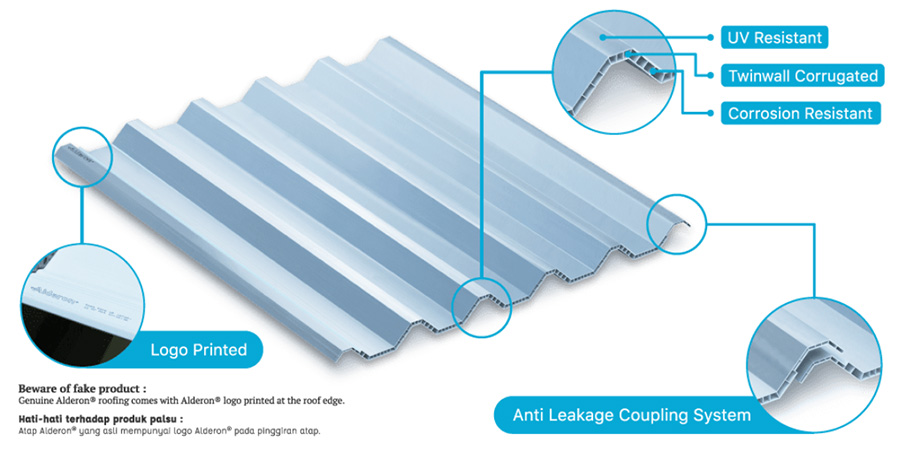

PVC hollow corrugated roof tile is widely used as factory roof, warehouse roof, agricultural market roof etc.The roofing tile has long service life. Good anti-corrosion ability and anti-impact ability. Fire proof, UV proof, noise isolation.Easy installation and low transportation cost.

Brand:

WONPLUSItem NO.:

SJZ+SJZ+YF1220Payment:

T/T, L/CProduct Origin:

Kunshan city, ChinaShipping Port:

Shanghai portLead Time:

60-75 daysIntroduction:

1. Wonplus manufactured plastic roof tile machine can make the surface of the roof tile is flat, color is uniform, and the hollow structure is perfect. Compared with PVC+ASA roof tile, PVC+PVC roof tile has the advantage of recycling and economic.While increasing the anti-ultraviolet and anti-aging properties, it can also save costs and facilitate recycling, which is the future development trend.

2. Wonplus PVC roof tile machine has two sets of extruder, one for PVC roof tile bottom layer, another for surface coextrusion (PVC or ASA layer), this plastic roof tile making machine has more options of material.

Equipment composition:

Conical Twin Screw Extruder + Hollow Roofing Tile Mould + Vacuum Calibration Table + Hauler + Cutter + Stacker

Feature:

● High output and stable running performance.

● PLC automatic control system and HMI touch screen control panel.

● Automatic mould temperature control system.

● Mould: The special flow channel structure of roofing sheet is adopted to make the material extruded evenly.

● Calibration Table : Adopt the pressure plate structure, the cylinder control, make the roofing sheet size accuracy control simple. The design of the cooling system pipeline makes the cooling of the roofing sheet more uniform and rapid shaping.

●Hauler and Cutter System: The caterpillar type combined hauler is used to make the traction measurement and adjustment simple, the caterpillar hauler and the Pneumatic cutter are controlled synchronously, and the cut of the plate is straight.

Technical Parameters:

PRODUCT NAME

PVC+ASA Hollow Roofing Tile

Coextrusion Line

PVC+PVC Hollow Roofing Tile

Coextrusion Line

EXTRUDER

SJZ-80/156

SJ-45/25

SJZ-80/156

SJZ-55/110

MAIN MOTOR POWER

55KW

7.5 KW

55KW

22 KW

PRODUCT WIDTH

800mm - 1220MM (or customized)

PRODUCT SPEED

0.8-2m/min

0.8-2m/min

Downstream Equipment

Vacuum calibration Table

1 set

Hauler

1 set

Cutter

1 set

Stacker

1 set