PVC four outlet pipe extrusion line has the model of 16-32mm four outlet and 32-63mm four outlet, which can produce Four pcs PVC pipes simultaneously. The small size PVC pipe is widely used to electric conduit, water discharge and so on. Four outlet PVC pipe extrusion line is a high efficient and output machine.

Brand:

WONPLUSItem NO.:

SJZ+GF4Payment:

T/T, L/CProduct Origin:

Kunshan city, ChinaShipping Port:

Shanghai portLead Time:

60-75 daysEquipment composition:

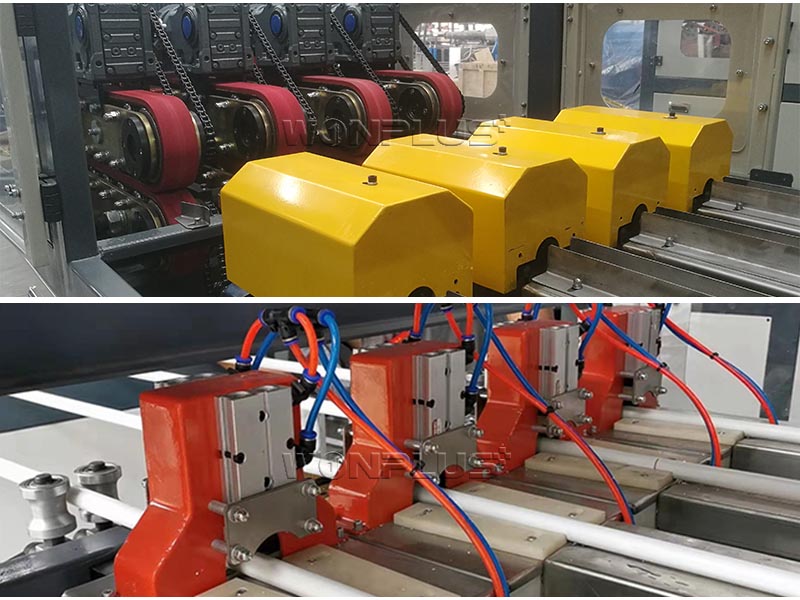

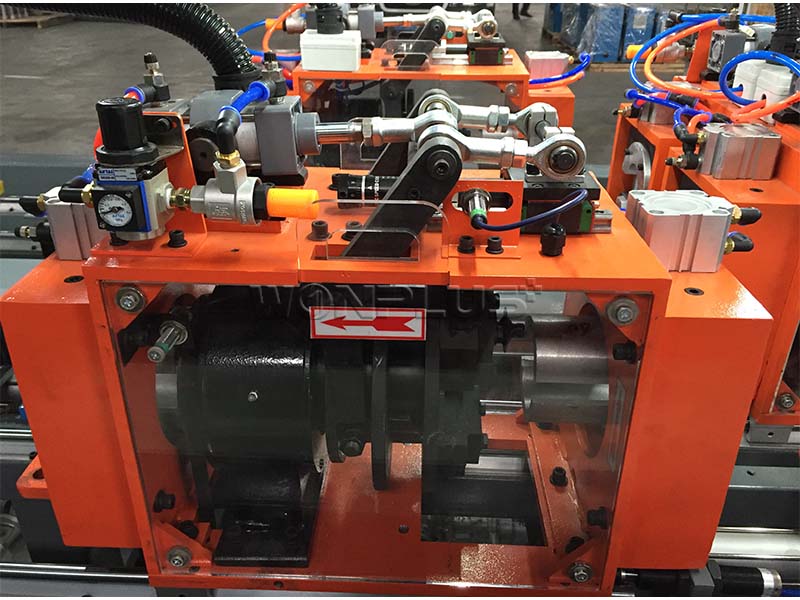

Conical Twin Screw Extruder + Four out PVC Pipe Mould + Vacuum calibration tank + Belt/Caterpillar type Hauler + Dust-free Cutter + Stacker

Features:

● Extruder controlled by Digital display control instrument, or PLC control system with HMI touch screen control panel,

● Vertical type integrated gearbox, with high torque, accuracy and durable performance.

● Bimetallic screw and barrel; Screw inner temperature controlled by thermo oil pump system; Equipped with degassing zone; Optimized double screw material feeding system for stable production of PVC powder.

● High production capacity: Under the premise of ensuring product quality, the four outlet PVC pipe extrusion line can reach about 12000kg per 24 hours.

● Small water and air consumption: WONPLUS optimized cooling water channel and air circuit make the water and air consumption reduce at least 25% than traditional type.

● Low noise pollution: WONPLUS machine use Dust free cutter, almost none sound while working.

● Low dust pollution: The traditional saw cutter makes serious dust pollution while working, and too much material wasted after cutting. But WONPLUS dust free cutter use Alloy knife, almost none dust while working.

Technical Parameters:

16-32mm Four outlet PVC pipe extrusion line

|

Extrusion System |

|||||||

|

Extruder |

Model |

Driven Motor |

Rotary Speed |

Capacity (kg/h) |

|||

|

Conical twin screw extruder |

SJZ-65/132 |

37kw |

34.7rpm |

300-400 |

|||

|

Downstream Equipment (16-32mm Four outlet) |

|||||||

|

Vacuum calibration tank |

Hauler |

Cutter |

Stacker |

||||

|

Length: 5000mm |

8 belt type |

Dust-free |

Length:6000mm |

||||

|

Vacuum pump:4kw*2sets Water immersed cooling |

Servo motor 0.75kw*8sets |

Cutting power: 400W * 4pcs |

|||||

|

0-12m/min |

|||||||

|

Extrusion System |

|||||||

|

Extruder |

Model |

Driven Motor |

Rotary Speed |

Capacity (kg/h) |

|||

|

Conical twin screw extruder |

SJZ-80/156 |

55kw |

34.7rpm |

400-500 |

|||

|

Downstream Equipment (32-63mm Four outlet) |

|||||||

|

Vacuum calibration tank |

Hauler |

Cutter |

Stacker |

||||

|

Length: 6000mm |

8 pedrail type |

Dust-free |

Length:6000mm |

||||

|

Vacuum pump:4kw*2sets Water immersed cooling |

Servo motor 0.75kw*8sets |

Cutting power: 400W * 4pcs |

|||||

|

0-11m/min |

|||||||

Extrusion Line Details: